Responsibility

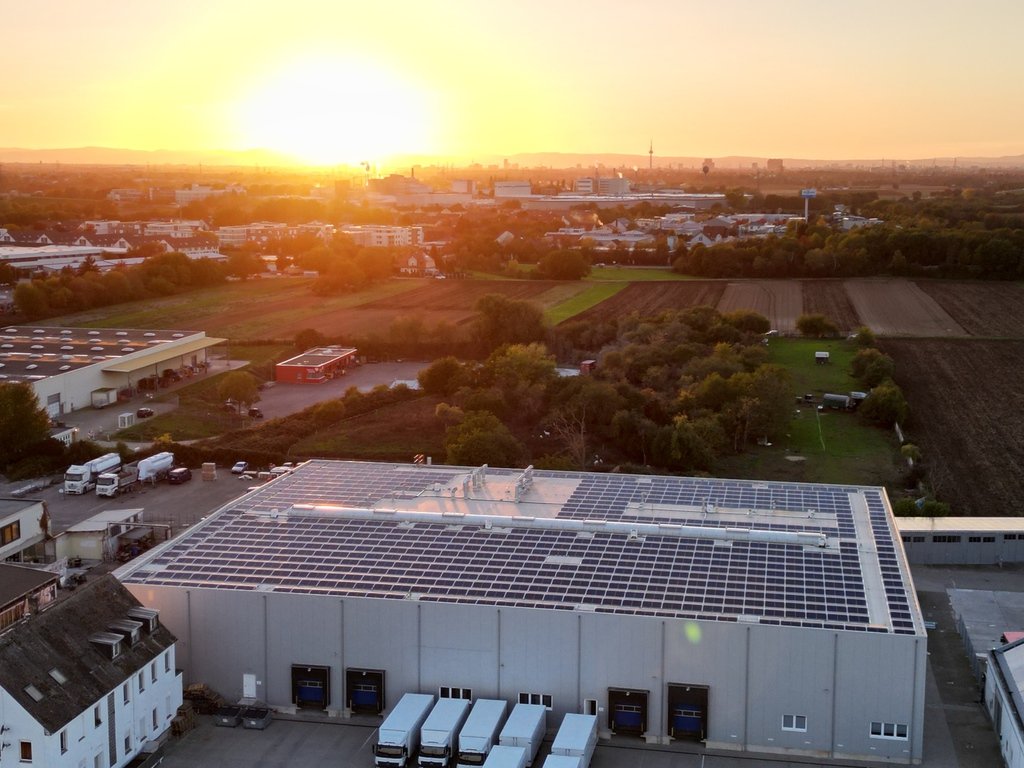

SolNet generates significantly more than 100% of the electricity consumed on the premises with the photovoltaic system installed on the company headquarters and storage areas. This includes the electricity needed for the electric vehicles in the fleet.

All cars in the fleet have been powered exclusively by electricity since 2018. The first electric vehicle we deployed in 2018 was a Tesla Model X. It is still in daily operation and has now covered nearly 300,000 km. Additional Tesla Model 3 and Model Y vehicles complete the fleet.

In the commercial vehicle sector, we still have to use Euro-6 diesel due to a lack of suitable alternatives. However, machines such as wheel loaders and forklifts are electrically driven at our facilities. For the small tools needed for the maintenance and construction of open-space systems, such as chainsaws, brush cutters, and hedge trimmers, we also use battery-operated devices.

At all solar parks we construct, we provide charging options for electric vehicles and machinery. Photovoltaic systems are installed on the roofs of the storage halls we use and at the company headquarters, and there are also charging options for electric vehicles. At Tesla Superchargers used for long-distance travel, only electricity from renewable sources is used.

The commercial use of electric vehicles requires a rethink in tour and construction site planning. This is a challenge we are happy to meet, as thinking is one of our core competencies!

Here you see our teams and the sun at work!

Open Space Project Development

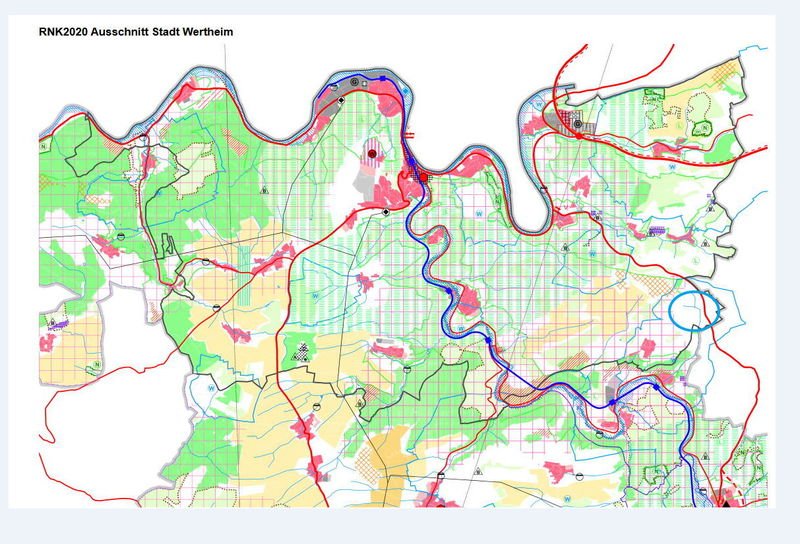

We conduct project development for large-scale open space projects on behalf of Trianel GmbH. Trianel GmbH is a network of 58 municipal utilities. Additionally, we have a development partnership with EnBW.

Our focus for open space installations is on developing projects starting from 10 MW, which corresponds to approximately 10 hectares of land. Our main area of activity is in Southern Germany, but we operate nationwide. The projects we develop typically participate in the Federal Network Agency's tenders for EEG compensation. We also develop projects for which a subsidy-free compensation of the produced electricity occurs outside the EEG framework.

The largest subsidy-free project we have developed is also the largest PV project in Baden-Württemberg, the Langenenslingen Solar Park on the Swabian Alb. This project, developed in partnership with EnBW, covers an area of 80 hectares and will have an installed capacity of 80 MW. Construction began on March 4, 2024, as mentioned in the news section.

After successful project development, we construct open space installations as the general contractor (EPC) for our own portfolio and for third-party investors.

Construction open space

Ottersweier 1 MW

Hochscheid 0.75 MW

Morbach 2.5 MW

Neuhausen 1 MW

Ottersweier 1 MW

Pettendorf 3.2 MW

Hochscheid 0.75 MW

Morbach 2.5 MW

Neuhausen 1 MW

Ottersweier 1 MW

Pettendorf 3.2 MW

Hochscheid 0.75 MW

Neuhausen 1 MW

Ottersweier 1 MW

Pettendorf 3.2 MW

Hochscheid 0.75 MW

Ottersweier 1 MW

Pettendorf 3.2 MW

Hochscheid 0.75 MW

Ottersweier 1 MW

Hochscheid 0.75 MW

Ottersweier 1 MW

Ottersweier 1 MW

Ottersweier 1 MW

Ottersweier 1 MW

Morbach 2.5 MW

Ottersweier 1 MW

Pettendorf 3.2 MW

New Roof Installations

In 2022, PV roof installations in Southern Germany are doubly profitable. They produce environmentally friendly electricity south of the network bottleneck, exactly where it is needed, and they generate a handsome return for the operator. This is made possible by combining self-consumption with the feed-in of excess electricity for feed-in tariffs. Even roofs not facing south can now profitably accommodate PV installations thanks to advanced module technology and adjusted consumption profiles.

We are happy to analyze your roof area and provide you with a free quote for your PV roof installation starting from 200 kW of installed capacity.

Roof Installation Maintenance

A photovoltaic system produces reliable, environmentally friendly electricity for the public and yields for the investor over decades, provided that the system is correctly configured and built according to applicable standards. Especially in the early years of PV technology, this was not always ensured. A result of deficiencies in planning and construction can be reduced yields, which may cause painful financial losses for the operator over the lifetime of the system.

Regardless, like any technical installation, PV systems must be inspected and maintained at regular intervals. Those who value maintaining their insurance coverage should comply with the relevant requirements.

At least every 4 years, a recurring inspection must be performed according to the standard for Grid-Connected Photovoltaic Systems - Minimum Requirements for System Documentation, Commissioning Tests, and Recurrent Inspections, DIN EN 62446-1 / VDE 0126-23-11. We are pleased to conduct this inspection with highly qualified experts. Common defects found in older installations include:

Errors in system planning and inverter allocation, leading to reduced yields

Missing or incomplete system documentation, causing complications in the event of damage

Dirty modules, leading to reduced yields

Missing or faulty grounding of the PV system, which can lead to severe damage and loss of insurance coverage

We analyze the existing documentation, assess the yield levels of the past years in advance, and inspect the PV system on-site.

Defects are rectified by our experts, and a complete system documentation with a measurement report is created. This prevents yield losses due to defects for the remaining lifespan of the system.